XUYI OUGE ELECTRONIC CO.,LTD

SINCE 2000 CONCENTRATE ON FERRITE CORE,BOBBIN,FERRITE CORE,INDUCTOR

Quickly Contact

Share to:

Iron power core

Details

Product Paramenters

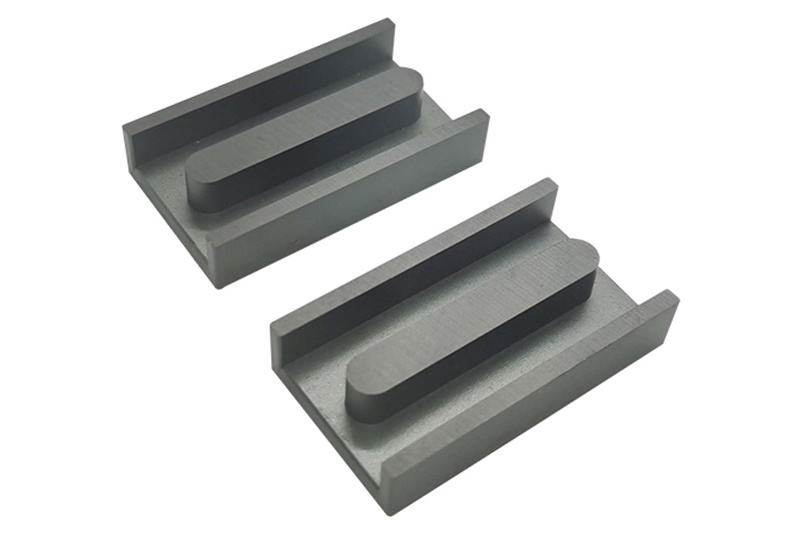

IRON POWER CORE

It is a product with high flux density, low cost and large energy storage capacity, which is often used in high-frequency chokes, switching power supply output chokes, conducted EMI noise filters, pulse transformers, DC output/input filters, etc

Product Basic Characteristics Reference Table

| Core Materials |

Core Loss | Perm.vs DC Bias |

Relative COS |

Frequency range |

Curie Temp |

F|Ux Density(sat.) |

Tem Stability |

| Iron Power | High | Good | Lowest | 100KHz | 750℃ | 12,000G | Poor |

| Sendust | ow | Good | LoW | 2MHz | 600℃ | 10,500G | Good |

| Sl-Fe | Medium | Best | Low | 1MHz | 700℃ | 16,000G | Best |

| High Flux | Low | Best | High | 1MHz | 500℃ | 15,000G | Best |

| Mpp | Lowest | Better | Highest | 1MHz | 400℃ | 7,500G | Best |

| Ferrite(gapped) | Lowest | Poor | Low | 1MHz | 200℃ | 4,500G | Poor |

Product Dimension

| NO | OUGE Part No. | Al nH/N^2 |

OD mm |

ID mm |

HT mm |

l cm |

Ae cm^2 |

V mm^3 |

| 1 | AT50-18B | 32.0 | 12.7 | 7.7 | 6.35 | 3.19 | 0.148 | 0.471 |

| 2 | AT50-38B | 49.5 | ||||||

| 3 | AT50-52B | 43.5 | ||||||

| 4 | AT60-18 | 34.5 | 15.2 | 8.53 | 5.94 | 3.74 | 0.178 | 0.699 |

| 5 | AT60-26 | 50.0 | ||||||

| 6 | AT60-40 | 41.5 | ||||||

| 7 | AT60-52 | 47.0 | ||||||

| 8 | AT72-18 | 60.0 | 18.3 | 7.11 | 6.6 | 4.01 | 0.349 | 1.40 |

| 9 | AT72-26 | 90.0 | ||||||

| 10 | AT72-40 | 71.0 | ||||||

| 11 | AT72-52 | 82.0 | ||||||

| 12 | AT80-18B | 46.5 | 20.2 | 12.6 | 9.53 | 5.14 | 0.347 | 1.78 |

| 13 | AT80-26B | 71.0 | ||||||

| 14 | AT80-38B | 72.0 | ||||||

| 15 | AT80-40B | 59.0 | ||||||

| 16 | AT80-52B | 63.0 | ||||||

| 17 | AT90-18 | 47.0 | 22.9 | 14.0 | 9.53 | 5.78 | 0.395 | 2.28 |

| 18 | AT90-26 | 70.0 | ||||||

| 19 | AT90-40 | 57.0 | ||||||

| 20 | AT106-18 | 70.0 | 26.9 | 14.5 | 11.1 | 6.49 | 0.659 | 4.28 |

| 21 | AT106-26 | 93.0 | ||||||

| 22 | AT106-28 | 30.0 | ||||||

| 23 | AT106-30 | 30.0 | ||||||

| 24 | AT106-33 | 40.0 | ||||||

| 25 | AT106-34 | 40.0 | ||||||

| 26 | AT106-35 | 40.0 | ||||||

| 27 | AT106-38 | 108.0 | ||||||

| 28 | AT106-40 | 81.0 | ||||||

| 29 | AT106-52 | 95.0 | ||||||

| 30 | AT130-18 | 58.0 | 33 | 19.8 | 11.1 | 8.28 | 0.698 | 5.78 |

| 31 | AT130-26 | 81.0 | ||||||

| 32 | AT130-28 | 25.0 | ||||||

| 33 | AT130-30 | 25.0 | ||||||

| 34 | AT130-33 | 33.5 | ||||||

| 35 | AT130-34 | 33.5 | ||||||

| 36 | AT130-35 | 33.5 | ||||||

| 37 | AT130-38 | 90.0 | ||||||

| 38 | AT130-40 | 69.0 | ||||||

| 39 | AT130-52 | 79.0 | ||||||

| 40 | AT131-26 | 116.0 | 33 | 16.3 | 11.1 | 7.72 | 0.885 | 6.84 |

| 41 | AT131-52 | 108.0 | ||||||

| 42 | AT141-26 | 75.0 | 35.9 | 22.4 | 10.5 | 9.14 | 0.674 | 6.16 |

| 43 | AT141-40 | 60.0 | ||||||

| 44 | AT141-52 | 69.0 | ||||||

| 45 | AT157-18 | 73.0 | 39.9 | 24.1 | 14.5 | 10.1 | 1.06 | 10.7 |

| 46 | AT157-26 | 100.0 | ||||||

| 47 | AT157-38 | 112.0 | ||||||

| 48 | AT157-40 | 86.0 | ||||||

| 49 | AT184-26 | 169.0 | 46.7 | 24.1 | 18 | 11.2 | 1.88 | 21 |

| 50 | AT184-33 | 70.0 | ||||||

| 51 | AT184-40 | 143.0 | ||||||

| 52 | AT200-18 | 67.0 | 50.8 | 31.8 | 14.0 | 13.0 | 1.27 | 16.4 |

| 53 | AT200-26 | 92.0 | ||||||

| 54 | AT200-33 | 37.0 | ||||||

| 55 | AT200-40 | 79.0 | ||||||

| 56 | AT200-52 | 92.0 | ||||||

| 57 | AT200-18B | 120.0 | 50.8 | 31.8 | 25.4 | 13.0 | 2.32 | 30.00 |

| 58 | AT200-26B | 160.0 | ||||||

| 59 | AT200-30B | 51.0 | ||||||

| 60 | AT200-35B | 74.0 | ||||||

| 61 | AT200-52B | 155.0 | ||||||

| 62 | AT225-18 | 67.0 | 57.2 | 35.7 | 14.0 | 14.6 | 1.42 | 20.7 |

| 63 | AT225-26 | 98.0 | ||||||

| 64 | AT225-30 | 28.0 | ||||||

| 65 | AT225-33 | 37.0 | ||||||

| 66 | AT225-40 | 78.0 | ||||||

| 67 | AT225-52 | 92.0 | ||||||

| 68 | AT225-26B | 160.0 | 57.2 | 35.7 | 25.4 | 14.6 | 2.59 | 37.8 |

| 69 | AT225-34B | 67.0 | ||||||

| 70 | AT225-52B | 155.0 | ||||||

| 71 | AT260-18 | 128.0 | 67.9 | 40.7 | 25.4 | 17.1 | 3.45 | 59.0 |

| 72 | AT260-30 | 51.0 | ||||||

| 73 | AT260-33 | 76.5 | ||||||

| 74 | AT260-40 | 140.0 | ||||||

| 75 | AT260-52 | 175.0 | ||||||

| 76 | AT350-18 | 125.0 | 89 | 54.4 | 25.4 | 22.5 | 4.39 | 98.0 |

| 77 | AT350-30 | 50.0 | ||||||

| 78 | AT350-33 | 75.0 | ||||||

| 79 | AT350-40 | 137.0 | ||||||

| 80 | AT350-52 | 171.0 | ||||||

| 81 | AT400-18 | 96.0 | 102 | 57.2 | 16.5 | 25.0 | 3.46 | 86.4 |

| 82 | AT400-30 | 40.5 | ||||||

| 83 | AT400-33 | 55.0 | ||||||

| 84 | AT400-40 | 115.0 | ||||||

| 85 | AT400-52 | 131 | ||||||

| 86 | AT400-26D | 262.0 | 102 | 57.2 | 33 | 25 | 6.85 | 171 |

| 87 | AT400-30D | 81.0 | ||||||

| 88 | AT400-33D | 110.0 | ||||||

| 89 | AT400-40D | 230.0 | ||||||

| * Specifications and parameters can be customized according to customer design requirements. | ||||||||

WHY CHOOSE OUGE

1.OUGE have complete raw material industry chain including kinds of bobbin,ferrite core and other accessories.

2.OUGE have obtained certificates with ISO9001:2015,ISO4001:2015,REACH,POPs,ROHS, IATF16949-2016 to ensure the products meet the safety and health requirements of environmental protection.

3.OUGE have multiple automated productions lines and advance testing equipment.

4. Quality Guarantee:14 steps quality checking ensure our products 100% reaching the standards of safety and eco-friendly. ”0” complaints of quality.

5. OUGE have more than 20years R&D experience,we can offer 3D printing service and carving service for new project.

Inquiry

We will contact you within one working day. Please pay attention to your email.